What We Do

Product Development

From Trends to Excellence

We interpret the market and translate ideas into custom-made private label collections. Through continuous research, mastery of production processes, and innovation at every stage, we refine designs and explore new materials and methods to guarantee products that combine the quality of H.J. Hering with the essence of each client.

Knitting

Yarns that transform into possibilities

Dedicated to weaving innovation into every thread, our knitting department produces high-quality combed yarn knits. Each weave is crafted with precision, guaranteeing excellence, versatility, and superior quality.

Laboratory

Science and technology in every detail

In an advanced laboratory with high-tech equipment, we combine science and technology to perform several tests, such as dimensional, solidity, peeling, friction, pH, grammage, and color monitoring in light booths. A rigorous technical approach that ensures reliable results and top-quality products for demanding brands.

Pattern Making/Layout

Precision that generates efficiency

With state-of-the-art plotters, we guarantee perfect layouts, maximum fabric utilization, and cost reduction. The technology ensures quality and precision in every pattern, without sacrificing operational agility.

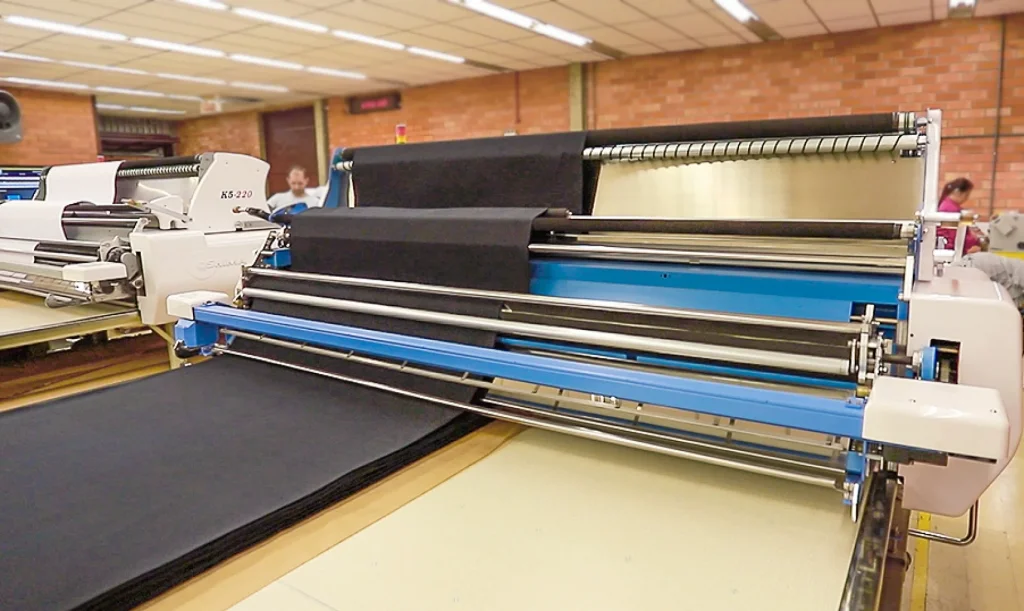

Spreading/Cutting

Perfect cuts, fast processes

Using state-of-the-art automated equipment for openwork and tubular mesh, we ensure standardization, speed, and excellence in all stages of spreading and cutting. A process that combines efficiency and reliability.

Embroidery

Embroidered quality of excellence

With high-resolution electronic embroidery machines, we offer sophisticated and versatile applications. To elevate product quality in every detail and deliver precision, refinement, and differentiation in each garment, we constantly update and bring more modernity to our manufacturing facilities.

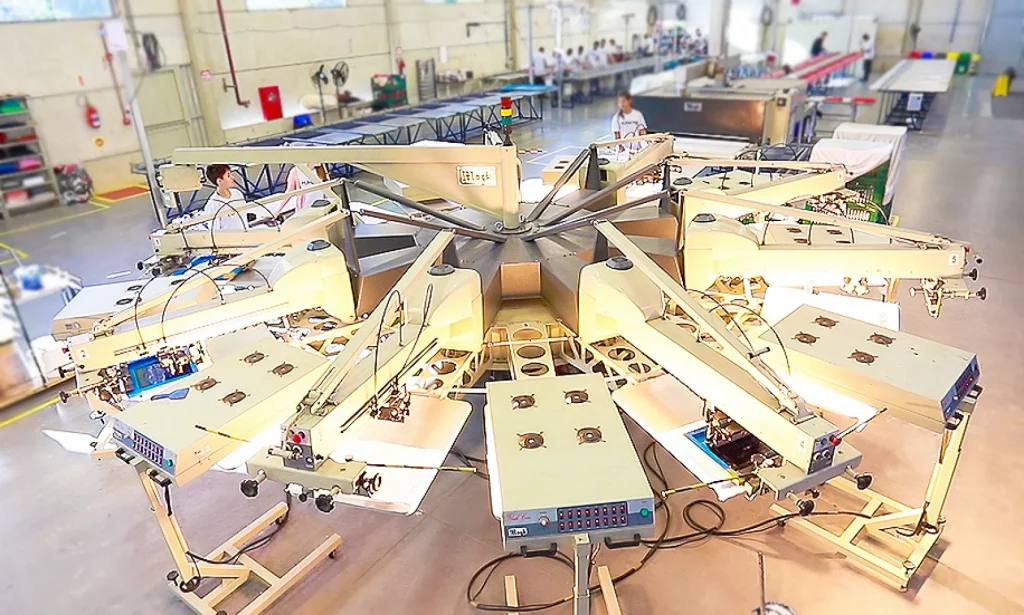

Printing

Technology that colors possibilities

Here, quality is printed with innovation. Our automatic carousel-type machines use multiple techniques to print any type of product with speed and precision. A process that gains even more agility and efficiency with the computerized pigment mixer.

Preparation

Agility before production

With cutting-edge technology, the preparation sector optimizes steps and ensures fluidity before the product enters the production cells. It means more speed and operational efficiency to meet the demands of our customers.

Sewing

Skilled hands, advanced technology

We combine human talent and technological innovation to craft garments with perfection, reflecting our commitment to excellence. With a highly qualified team operating on the production line and constant investment in training, we have created our high standard of quality, already acknowledged in the market.

Ironing and Packaging

Finishing that makes the difference.

The impeccable finishing in every detail and the perfect drape of our pieces are the result of modern steaming and ironing machines. All this care and excellence are present in the packaging stage, which, in addition to the exclusive customization of products, guarantees logistical agility and makes delivery more practical, efficient, and aligned with the needs of our partners.

Shipping/Packing

Safety and control in every shipment.

The excellence that begins in the preparation stage extends to the Shipping department. Through a rigorous and effective quality control process, each box is identified with a list of contents and goes through a metal detector, ensuring safety, traceability, and reliability in every delivery.

Social

People first.

Caring for people is part of our DNA, it's sewn into our essence. That's why we value our employees, who are the true raw material of our growth. We invest in training, development, workplace exercise, medical care, transportation, and meal vouchers. Because our success is woven with care and respect for those who make the difference.